What is dock scheduling?

Dock scheduling is planning the arrival and departure of vehicles at loading docks in a warehouse or depot. The aim is to create a schedule that respects a facility’s loading capacity and spreads loading activity over time. This avoids overwhelming loading peaks and the resulting delays.

Why use PTV OptiFlow for dock scheduling?

How does dock scheduling fit into your transport planning process? Are you defining fixed depot start times for vehicles, before creating their delivery routes? Or, are you manually correcting driver start times after determining their routes? Then you know this is a daunting task.

It involves aligning many factors such as dock availabilities, driver skills, work schedules, vehicle properties, and customer timings. Manually solving this puzzle takes a lot of time and easily leads to mistakes. On top of that, your decisions are impacting the costs of your delivery plan.

That’s where PTV OptiFlow comes in. As dock scheduling is directly integrated into PTV OptiFlow’s route optimization algorithm, depot start times and delivery routes are optimized simultaneously. This means depot capacity, transportation costs, and requirements are balanced all at once, reducing the total planning costs.

PTV OptiFlow’s dock scheduling solution also saves valuable planning time. All you need to do is specify the number of available docks at your depot or warehouse. This number can be fixed or fluctuate throughout the day. This flexibility ensures that your delivery plan matches your depot operations seamlessly and leaves maximum room for route optimization.

How does dock scheduling with PTV OptiFlow work?

Imagine you have over 100 drivers and vehicles operating out of your depot. Every day, they transport orders to numerous customers, all using different delivery time windows and constraints.

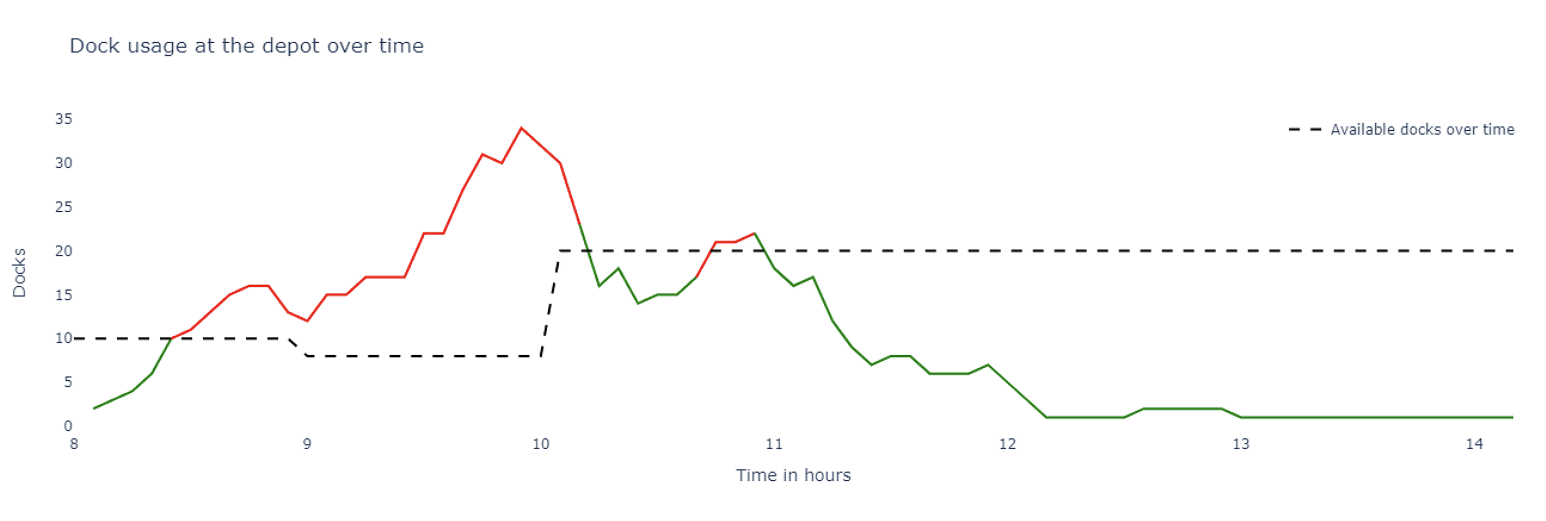

When creating today’s delivery plan using PTV OptiFlow without dock scheduling, dock usage in your depot throughout the day may look like this chart. There are multiple peaks in dock activity, and dock capacity is often exceeded. Just before 10 AM, no less than 34 vehicles are expected to be ready to load, while only 10 docks will be available. The outcome? Drivers lining up and money out the window.

How can you prevent this from happening?

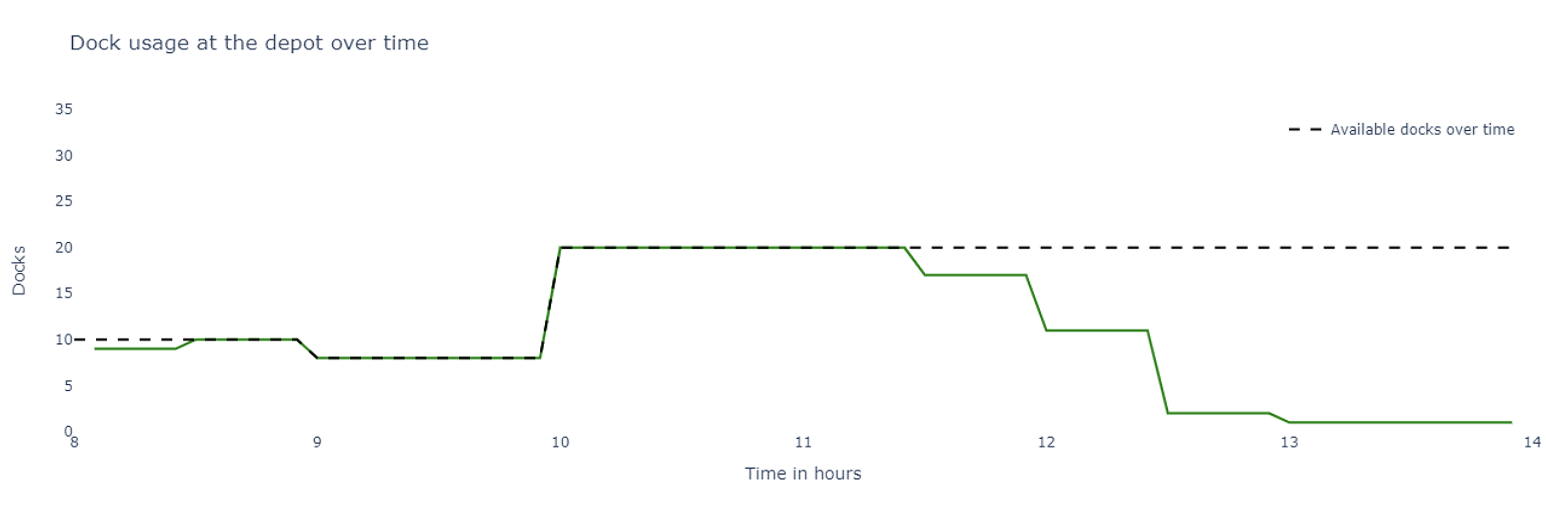

Just specify the number of available docks over time and let PTV OptiFlow generate an optimal transport plan respecting this limit. This time, the dock usage chart shows that the number of vehicles starting at the depot is more spread out over time and never surpasses the number of available docks. The result? Cost savings, happy drivers, and relaxed depot staff.

Benefits of dock scheduling with PTV OptiFlow

Benefits for warehouse or depot

Improved operational efficiency and time for other tasks safeguarded

Decrease pressure on personnel

Prevention of unsafe situations caused by inopportune parking of waiting vehicles

Benefits for drivers, customers & transport planner

For your drivers minimal frustration and stress over wait times

For your customers timeliness of deliveries increased

Your transport planner gained time through elimination of manual work and prevent human error

Benefits for your company

Cost optimization of delivery routes ensured by avoiding adaptation to manually determined depot start times

Cost savings through reduction of idle time, overtime, and dwell time fees

Boost in driver and employee retention and employer competitiveness

Are you ready to boost your transport efficiency using one streamlined solution for route optimization and dock scheduling?

Download this use case in PDF

More use cases

Cost Optimization with PTV OptiFlow

PTV OptiFlow inherently focuses on finding the most economical delivery plans by defining specific costs for various factors.

Integration of Deliveries & Pickups with PTV OptiFlow

Are your logistics operations hampered by the inefficiencies of separate delivery and pickup processes? PTV OptiFlow revolutionizes this process.

Simplify Route Planning Amid Complex Tariff Structures with PTV OptiFlow

PTV OptiFlow offers a sophisticated solution that integrates distinct costs at the order level for any subcontractor in your plan.

Enhancing Planning Reliability with PTV OptiFlow

PTV OptiFlow creates robust plans that eliminate the need for post-planning adjustments, ensuring optimal and reliable logistics operations.

Enhanced Prediction of Planned Arrival Times based on Historical Traffic Information in PTV OptiFlow

Tired of your drivers getting stuck in traffic and failing to meet your scheduled delivery times? PTV OptiFlow addresses this challenge.

Optimizing Outsourcing Decisions with PTV OptiFlow

Do you rely on rules of thumb to decide which volumes to outsource? PTV OptiFlow eliminates guesswork by leveraging the various cost structure details.

Mastering the Art of Choosing Between Cross Docking and Direct Delivery with PTV OptiFlow

Making strategic decisions on whether to cross dock a delivery for consolidation with other shipments or to proceed with direct delivery is crucial for operational efficiency.

Integrated Depot and Route Optimization with PTV OptiFlow

Are you tired of the task of breaking down your planning process by first assigning deliveries to a depot and then optimizing routes for each depot individually?